Managing heat dissipation has become a key component of electronic device design as they grow smaller and more potent. Effective cooling is necessary to provide dependability and longevity because heat can damage components and shorten lifespan. Nevertheless, cooling in constrained areas and restricted airflow is a problem that calls for creative solutions. Skived fin heat sinks provide effective heat dissipation in a small form factor, making them the ideal choice for cooling electronics in confined places and limited airflow situations. The advantages of the skived heatsink will be covered in this article, along with how they can help control the heat in difficult settings.

What are Skived Fin Heat Sinks?

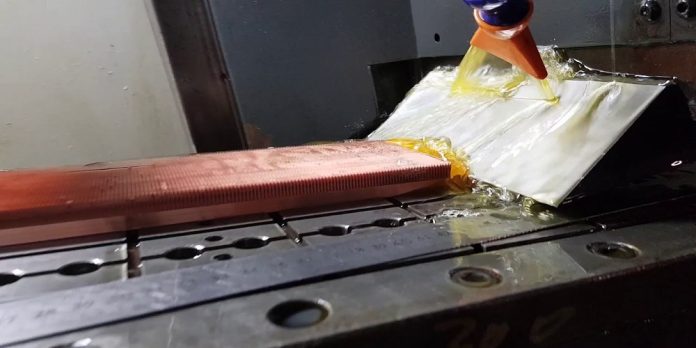

Skived fin heat sinks are produced utilizing a unique manufacturing procedure that involves cutting skinny, parallel fins on a metal substrate. This approach produces fins that are thinner than those made by previous techniques by continuously shaving a block of metal with a sharp blade. This innovative design maintains a small overall dimension while offering a substantial surface area for heat transfer. The resulting fins are more consistent and sharper than those made using other production techniques, enabling more effective heat dissipation.

Benefits of Skived Fin Heat Sinks

Skived fin heat sinks are superior to other cooling options in a number of ways, especially in environments with low airflow and confined spaces.

Compact Size

Skived fin heat sinks have a high surface area-to-volume ratio due to their thin, pointed fins, which enables them to provide effective cooling in a smaller area. They are, therefore, the perfect option for devices that need high cooling performance but have little room for heat dissipation. Skived fin heat sinks can also be made to fit particular designs, making the best use of available space.

Efficient Heat Transfer

The sharp fins of skived fin heat sinks allow for efficient heat transfer from the electronic components to the surrounding air. The fins’ high surface area creates a sizable area of contact for heat exchange, and their pointed edges encourage air mixing and enhance heat transfer. Due to this, skived fin heat sinks are more efficient than conventional heat sinks with larger fins, particularly in conditions of low airflow.

Low Thermal Resistance

The skived fin heat sinks’ thin, uniform fins have low thermal resistance, which improves heat dissipation. This implies that they can dissipate more heat with less power, leading to a cooling solution that uses less energy. Skived fin heat sinks have a low-pressure drop as well, which prevents them from obstructing airflow and lowering cooling efficiency.

Customizable Design

Skived fin heat sinks can be made to order to meet specific specifications, including fin density, size, and shape. This enables better cooling efficiency and space utilization. Depending on the particular application, skived fin heat sinks can also be made from a variety of materials, such as copper and aluminum.

Applications of Skived Fin Heat Sinks

Skived fin heat sinks are the best choice for cooling electronics in places with little airflow and confined spaces. They are frequently employed in the following:

- Servers and data centers: Where high-density computing calls for effective cooling in constrained areas.

- LED lighting: Skived fin heat sinks’ small size makes it possible to effectively cool highly powerful LED chips.

- Automotive electronics: A field in which cooling space is scarce and heat dissipation requirements are high.

- Medical devices: Skived fin heat sinks are the perfect option for portable devices needing effective cooling due to their compact size.

Conclusion

Skived fin heat sinks are a cutting-edge approach to controlling heat in difficult environments. They are perfect for cooling electronics in small spaces with low airflow because they offer effective heat dissipation in a small form factor. They are a great option for high-performance electronic devices because of their adaptable design, low thermal resistance, and effective heat transfer. Skived fin heat sinks are becoming an essential element in ensuring the dependability and longevity of these devices as the demand for small, powerful electronics grows.