How Are Schedule 80 Pipe Dimensions Verified for Quality?

Schedule 80 pipes are renowned for their strong development and high reliability, making them crucial in different businesses. Ensuring these pipes meet exacting quality standards is vital for their performance in high-pressure and requesting applications. The verification of Schedule 80 pipe dimensions for quality includes a comprehensive process that incorporates cautious fabric determination, exact manufacturing, thorough testing, and strict adherence to industry benchmarks.

This multifaceted approach guarantees that each pipe meets the fundamental decisions for ideal execution and reliability. By following these exacting quality confirmation forms, schedule 80 steel pipe maintain their reputation for durability and dependability, guaranteeing they can withstand the most challenging conditions in different mechanical applications.

Material Selection and Inspection

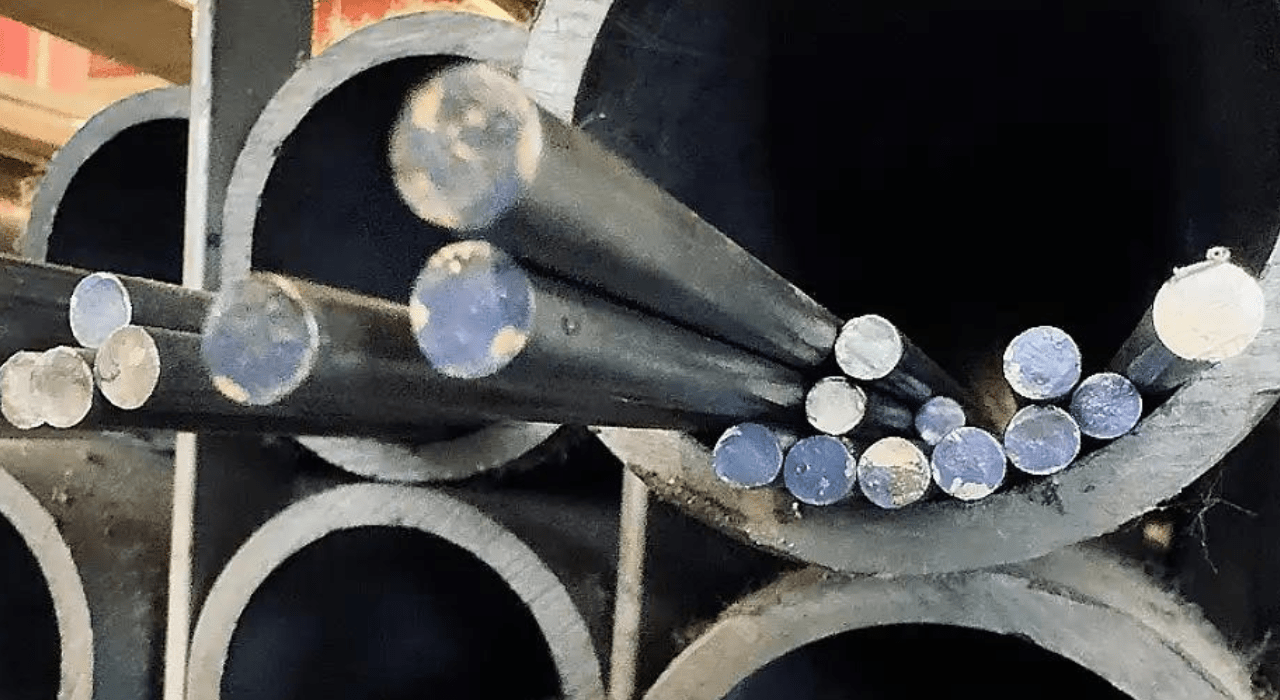

The quality verification preparation starts with the selection of raw materials. Schedule 80 pipes are regularly made from materials such as PVC, CPVC, and metal combinations like steel. Each material offers particular benefits, such as erosion resistance and high strength. To guarantee these materials meet the essential quality standards, producers conduct thorough inspections.

Accuracy Manufacturing Processes

Once the raw materials are approved, the manufacturing process can begin. Accuracy in manufacturing is pivotal to preserving the precise measurements required for Schedule 80 pipes. The method regularly involves extrusion (for plastic pipes) or welding and rolling (for metal pipes). Amid extrusion, warmed material is constrained through a pass-on to form the required pipe shape and measure.

Dimensional Confirmation

Dimensional confirmation is a basic step in ensuring Schedule 80 pipes meet quality guidelines. This includes measuring the pipes’ external distance across, inner diameter, wall thickness, and length. These estimations are taken using exactness rebellious such as calipers, micrometers, and laser estimation systems. The data collected is compared against the ostensible pipe estimate (NPS) and schedule details to guarantee compliance.

Damaging Testing

In expansion to NDT, dangerous testing is sometimes performed to confirm the quality of Schedule 80 pipes. This includes taking test pipes and subjecting them to tests that decide their mechanical properties, such as tensile quality, affect resistance and hardness. Whereas these tests destroy the test pipes, they give profitable information on the material’s execution under extraordinary conditions.

Compliance with Industry Standards

Adherence to industry benchmarks could be a principal viewpoint of quality confirmation for Schedule 80 pipes. Organizations such as the American Society for Testing and Materials (ASTM) and the Worldwide Organization for Standardization (ISO) set thorough guidelines for pipe measurements, fabric properties, and testing strategies. Producers must guarantee their items comply with these benchmarks to ensure execution and unwavering quality.

Documentation and Traceability

Quality verification for Schedule 80 pipes also includes thorough documentation and traceability. Each group of pipes is accompanied by detailed records that include data on raw materials, manufacturing forms, testing results, and compliance certificates. This documentation provides a comprehensive history of each pipe, ensuring traceability from generation to last utilization.

Continuous Quality Control

Quality verification does not end once the pipes leave the manufacturing office. Continuous quality control measures are essential to guarantee proceeded execution and reliability. This incorporates normal assessment and support of pipes in benefit, checking for signs of wear or damage, and conducting periodic testing to confirm their integrity.

Conclusion

Confirming the quality of Schedule 80 pipe measurements may be a comprehensive handle that includes material choice, accurate manufacturing, thorough testing, and adherence to industry guidelines. By utilizing a combination of non-destructive and damaging testing strategies, producers can guarantee that these pipes meet the stringent requirements vital for high-pressure and demanding applications. Thorough documentation and progressing quality control measures advance improve the unwavering quality of Schedule 80 pipes, making them a trusted choice in different businesses.